- English

- Nederlands

DFW Europe is an international producer and supplier of complete cremation solutions. They started as a central heating installation company and grew into a real Dutch machine factory led by father and son, Jan and Bart Keeman.

DFW Europe is an international producer and supplier of complete cremation solutions. They started as a central heating installation company and grew into a real Dutch machine factory led by father and son, Jan and Bart Keeman.

In the beginning, DFW gained much experience in industrial gas heaters and filter systems during the construction of greenhouses. This was followed by a side-step into the installation of imported cremation ovens that would later prove to be all-decisive. Eventually DFW very successfully took control by providing the entire development, construction and final assembly of complete cremation installations.

They choose a PAC control system from Opto22 because of the enormous flexibility of the hard and software and the lack of licensing costs for the programming and HMI software. The innovative solutions on offer to the cremation market nowadays are the result of more than 25 years of knowledge and experience.

Jan Keeman: “DFW has gone deeper into the technology to refine and optimise the process even further.

As a company, the trick is to program all aspects of the cremation process in the machine and thereby combine the feeling for the mechanical side, the instructions and the installation.”

The Challenge

DFW has designed a cremation installation with five cremation ovens with state-of-the-art technology for a crematorium in Ringsted, Denmark. One of the requirements was that the brand-new cremation ovens could be controlled by the operators with smart phones.

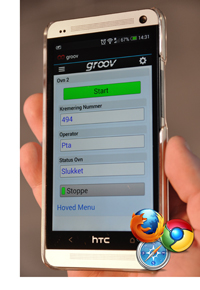

DFW had already progressed far with a solution for scanning the cremation numbers with smart phones; however a separate IR remote control was required for operating the ovens until Opto22 groov came onto the market! Now the challenge was to implement Opto22 for this prestigious project within a very short period…

Jan en Bart Keeman: “Opto22 groov came out at the end of the project. It was exactly what we were looking for because the interface can be operated perfectly with a smart phone!”

Jan en Bart Keeman: “Opto22 groov came out at the end of the project. It was exactly what we were looking for because the interface can be operated perfectly with a smart phone!”

The Solution

Up until now the IR control was the only option for controlling the cremation ovens. This changed with the arrival of Opto22 groov and it became possible to operate the cremation ovens with mobile devices such as smart phones.

The fact that Opto22 groov communicates with non-Opto22 hardware just as easily as with Opto22 hardware was the second important factor in the decision to adapt the original plan.

Bart Keeman: “The use of Opto22 and groov have enabled DFW to raise the quality and lower the cost of the electronics and licences.”

The Implementation

A test set-up was developed in one morning thanks to the cleverly designed development tool with tag database. Testing could start after the training video had been watched, the groov-box had been connected to the network and the connection with groov via a web browser had been established…

Bart Keeman: “We phoned on Thursday to ask if we could try a test set-up. We received it Friday morning and our first groov-interface was working in the test environment on Friday afternoon.

After a short testing phase, the now extremely enthusiastic engineers from DFW could quickly start programming the final user interface for the Danish crematorium. Within a couple of weeks DFW has been able to definitively implement the groov screen in the production environment.

The result

The result

The operators can now operate the whole cremation process with a smart phone and keep an eye on the status of the oven at all times. The interface developed here has been kept simple and basic. When the coffin is inserted into the cremation oven the operator only has to enter his name and scan the registration number of the coffin, and then press the start button. The whole process is then controlled fully automatically.

The DFW cremation ovens are very energy-efficient and extremely low in emissions due to the many technical innovations developed by DFW in the cremation process. Hundreds of homes, two schools and a swimming pool in Ringsted are heated with the recovered energy. The new crematorium is therefore known as ‘Cremation 2.0’ in the cremation market.

Mulder-Hardenberg is extremely proud to have been able to contribute to this.